Corrugated Flute Sizes: A, B, C, E, F (and Why the Alphabet Is Lying to You)

If you’ve ever stared at flute sizes and thought, “Who designed this system—an evil alphabet wizard?”… same.

Flute size is one of the most common misunderstandings in packaging, mostly because the labels do not go in a clean “big to small” order. It’s like T-shirt sizing where “medium” means “maybe” and “one size fits all” means “one size fits the hanger.”

Today we’re talking about the corrugated you see in most shipping boxes: one fluted medium glued between two liners (a.k.a. single-wall).

Quick note before the flute police show up: “single-face” technically means one liner with exposed flutes (often used for wrapping/protection), but a lot of people casually say “single-face” when they mean single-wall. For boxes, we’re talking the two-liner sandwich.

Double-wall, paperboard, and all the other fun stuff? We’ll save that for another day.

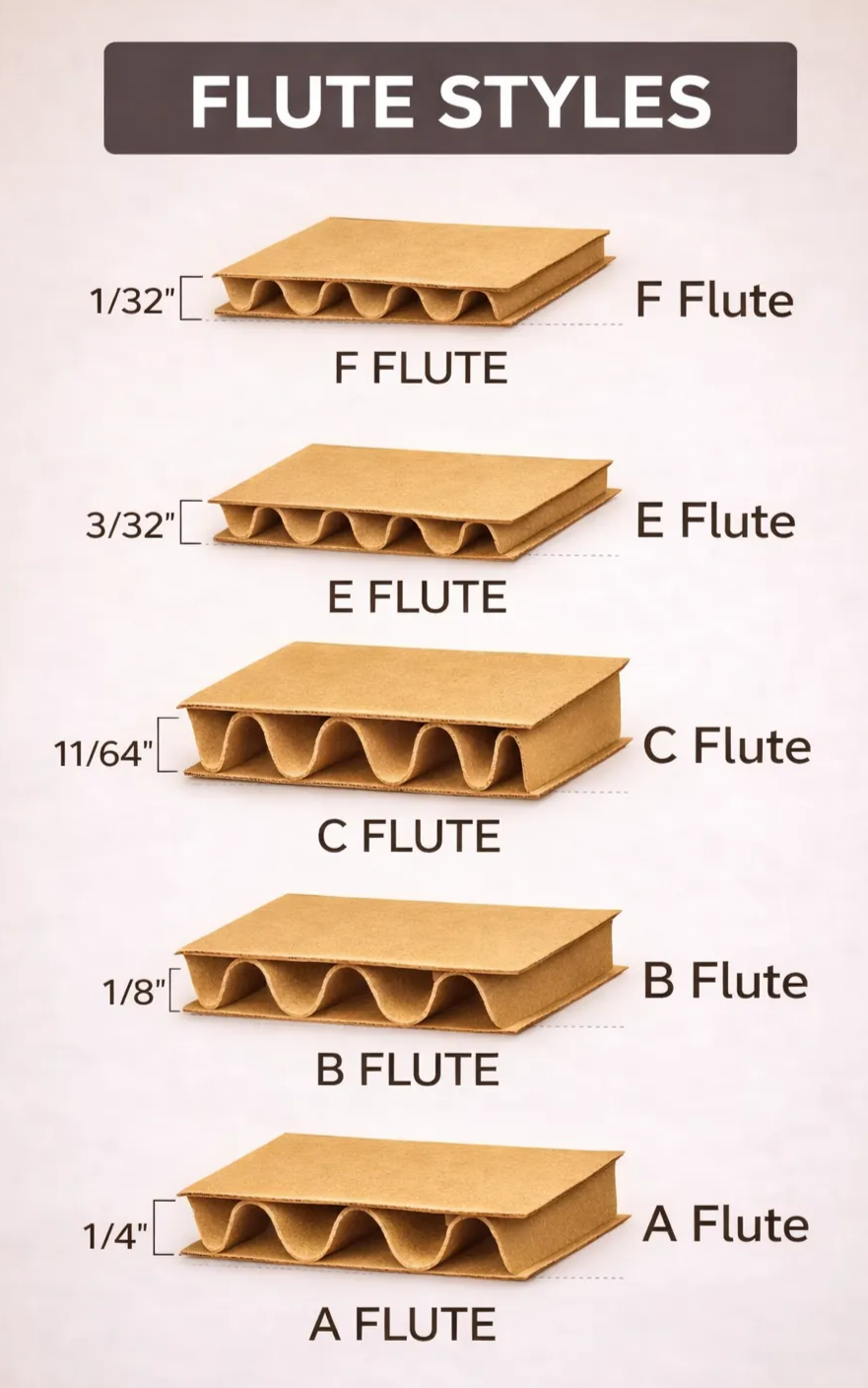

The common flute sizes (rough thickness)

Here are the flute types you’ll most often run into. Thickness is approximate and can vary by manufacturer, liner weights, and board construction. Think “rule of thumb,”

| Flute | Typical “Feel” | Approx. Thickness (inches) |

|---|---|---|

| A | Big, cushy | ~ 1/4" |

| C | The classic workhorse | ~ 3/16" |

| B | Thinner + tougher feel | ~ 1/8" |

| E | “Micro-ish,” cleaner looking | ~ 1/16" (sometimes a bit more) |

| F | Very thin, very smooth | ~ 1/32" |

And yes… B is thinner than C.

So why is B smaller than C?

Because the letters are historical, not logical. They were basically assigned as flute profiles were developed/adopted—not as a nice, tidy size ranking. Packaging is full of these little “because we’ve always done it that way” gems. (Cherish them. Or don’t. Either is fine.)

The 3 things you should watch when selecting flute size

When you change flute size, you’re really changing three things:

How much paper is in the board (changes material cost)

How thick the box is (changes shipping cube / dimensional weight)

How the box performs (changes strength, damage rates, packing line efficiency)

Let’s break it down without putting anyone to sleep.

1) Flute size vs. cost per square foot (material cost)

Think of corrugated like a sandwich:

Two flat papers (liners)

One wavy paper (medium)

The wave is the key. When the waves are bigger, the medium has to travel a longer “wavy road” to cover the same flat area—meaning more paper gets used.

Bigger waves = more medium = more material = more cost (all else equal)

So, generally:

Bigger flutes (A, C) = more material

Smaller flutes (B, E, F) = less material

Flute size comparisons

Flute comparison

Reality check: Cost isn’t only flute size. Liner weights, board grade, availability, and converting can matter a lot. But as a baseline, flute size absolutely affects how much paper you’re buying.

2) Flutes and volume (shipping cube / DIM weight)

Flute size changes board thickness, which changes outside carton dimensions.

If your product stays the same (inside dimensions fixed), switching to a thinner flute can shrink the outside of the box. That can reduce:

Dimensional weight (parcel carriers)

Cartons per pallet

Truck space

Warehouse space

A quick real-world example (no calculus, I promise)

Let’s say your product needs an inner box size of 12" × 12" × 12".

With a thicker board (say ~3/16" caliper), your outside size is roughly:

12 + (2 × 0.1875) = 12.375" per side

With a thinner board (say ~1/16"), your outside size is roughly:

12 + (2 × 0.0625) = 12.125" per side

That doesn’t sound like much… but the shipping cube drops by about 6% in this example.

And if you ship a lot of parcels where DIM weight is king, 6% is the difference between:

“Nice savings”

and “Why are our shipping costs quietly eating us alive?”

Bottom line: If you pay for cube/DIM, flute thickness can be a real money lever.

3) Why flute size matters even when volume doesn’t

Even if you’re not paying by cube (example: full truckloads, or you’re consistently weight-limited), flute choice still changes cost because it changes performance.

A) Damage risk (cushioning and forgiveness)

Generally:

Bigger flutes (A/C) give more cushion and are more forgiving in rough handling.

Smaller flutes (B/E/F) are thinner and less forgiving unless the design compensates (better inserts, tighter fit, stronger grade, etc.).

If you go too thin and damage increases, you don’t just lose product—you lose time, customer trust, and margin. And returns are the gift that keeps on taking.

B) Strength / stacking performance

Boxes need to survive:

Stacking in a warehouse

Pallet loads

Compression during storage and transit

Humidity swings (because paper loves drama)

Depending on the design and board grade, a flute change can improve one performance trait while hurting another. Translation: don’t guess—verify.

C) Packing line efficiency + print quality

Smaller flutes often:

Fold cleaner

Score better

Look better printed (smoother surface = nicer graphics)

Those savings are real—especially at scale—because they show up as:

Less scrap

Less rework

Fewer jams

Fewer “why is this box doing that?” meetings

Quick cheat sheet: when each flute tends to make sense

Use this as a starting point, not a final answer.

A flute: Great cushioning and thickness. Solid choice when protection is the priority.

C flute: The all-around workhorse. Common for shipping cases.

B flute: Thinner than C, often a nice balance of strength and flatter surface.

E flute: Good when you want a thinner, cleaner-looking pack (often used in retail-style packaging too).

F flute: Very thin, smooth, great graphics potential—also less forgiving, so design matters a lot.

A practical tip: how to right-size flute without guessing

If you want to do this yourself, here’s a simple approach that works:

Step 1: Pick one SKU and downsize one step

Choose one product and try a thinner flute (for example: C → B, or B → E).

Step 2: Validate it (two solid paths)

Option A: Distribution testing

If you have access to formal test standards or a lab, run a distribution-style test (drop, vibration, compression). This is the “prove it” route and it saves you from expensive surprises.

Option B: “Shake, rattle, roll” + real-world rollout

This is the scrappy but effective method:

Drop it from multiple angles

Toss it (yes, toss it)

Chill it, heat it, humidify it, then drop it again

Simulate the worst day your package could ever have

Because let’s be honest: delivery can look like a highlight reel of gravity winning.

If it survives your internal abuse testing:

Release it in small batches

Track damage and returns vs. baseline

If damage rises → revert fast

If damage stays flat (or improves) → you’ve got a winner

I’ve heard this floating around the industry for years and it’s still true:

A test is worth 1,000 opinions.

Wrap-up

Flute size isn’t just a random spec you pick because “that’s what we’ve always used.” Changing flute size can affect:

Material cost

Shipping cost

Damage rates

Stacking strength

Line efficiency

Print appearance

In other words: it’s a small choice that can have big consequences (good or bad).

If you want to optimize it, pick one SKU, change one thing, and test it like the world is trying to break it—because it is.

Want help with this?

If you want to work with a professional on flute selection, cost reduction, or testing strategy, feel free to contact me via the contact page. Or below!

Thanks for reading!

Brett